The Opportunity for Sustainable Product Development

Every year, more than 79 million motor vehicles, 4 billion toothbrushes, and 23 billion pairs of sneakers are manufactured. One and half billion phones, 340 million PCs, around 8 billion clothes hangers, 210 million TVs are sold.

Over the last 50 years, global use of materials has nearly quadrupled.

This creates an interesting paradox. We are more reliant on products than ever before, and there are often produced in more quantities than ever before. Our reliance on these everyday products, however, is threatening our ability to continue living on this planet.

It’s estimated that 80 percent of all product-related environmental impacts are determined at the design phase of a product. Think about that: Before a product ever gets into the hands of consumers, most of its impact on the Earth has already been decided. Damage has already been done.

So, to minimize the impact products have, what if we fundamentally – and radically – changed the way we make products?

Choices like what materials the product will be made from, where those materials will be sourced from, and how the product will be shipped and packaged greatly impact the product’s ultimate carbon footprint over the course of its useful life. There are hundreds of other potential design and development choices that can have a downstream impact as well.

Why does this matter? It’s estimated that the production and use of household goods and services are responsible for 60 percent of global greenhouse gas emissions. If sustainability is more fully considered in the design and development decisions, it could significantly reduce the overall environmental impact of these products.

With the backdrop of rapidly accelerating climate change, PTC’s Chief Strategy and Sustainability Officer Catherine Kniker shared this opportunity for sustainable development as just one of the positive ways technology can play a role in addressing climate change at Women in Tech Boston 2022.

Describing climate change as the “greatest resiliency challenge that the human race will ever face”, she shared a message of hope and opportunity for action.

“All of us in this room, brought together by an appreciation for technology and its positive impact on the world, have an important role to play. Technology, across so many of its different forms, will be at the heart of the paths we take to address this challenge,” she said.

Kniker went on to elaborate that there are many angles women in tech can take to address climate change: energy production, transportation, agriculture, infrastructure, but stressed that technology is often the means toward progress. Whether it’s creating innovative climate tech, moving to electric vehicles for business operations, or using improved tools for product design and development.

“There is massive opportunity for companies to rethink the way that they design their products. A greater focus on modular design. A bigger emphasis on designing for recyclability. A higher priority on designing for disassembly, reusability, and re-manufacturing,” Kniker said.

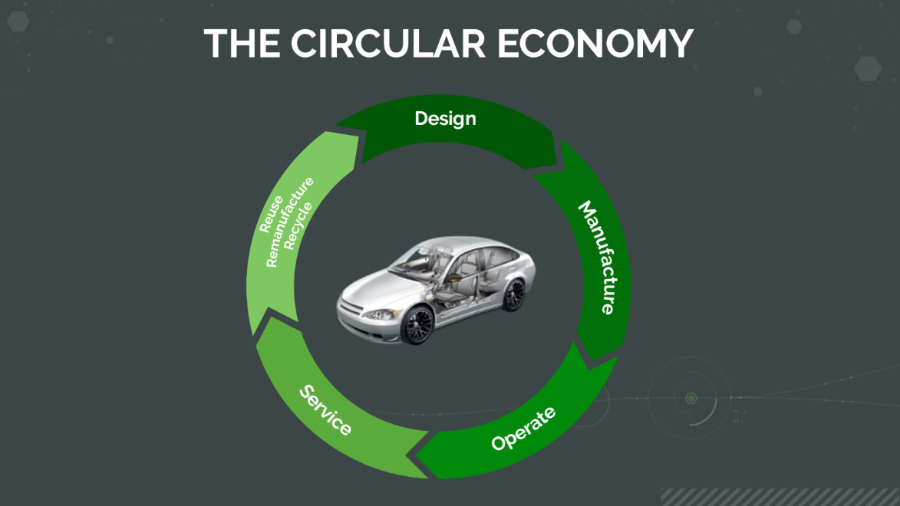

In other words, to combat climate change, manufacturers need to start considering sustainability across the entire product lifecycle – from design to manufacturing to service to end of life.

Technologies already exist to do much of this work. At PTC, our software can be used to support more sustainable design, manufacturing, and aftermarket service. A few examples:

- Computer-aided design (CAD) technology is helping Cummins optimize new product designs for the environments by using generative designs to reduce material use.

- Product lifecycle management (PLM) helps companies like Vestas, Bosch, and ZF to inform and validate their sustainability initiatives while promoting benefits of enterprise collaboration.

- IoT is helping Vattenfall optimize asset utilization via reduced downtime and energy consumption, while assuring sustainable service for customers.

- Augmented reality (AR) is helping e.GO build affordable electric cars with 3D assembly and quality testing instructions.

- Service lifecycle management (SLM) optimizes the inventory within the service supply chain, recommending when to move parts between echelons and distribution centers to maximize equipment uptime and readiness.

Thinking Differently About Sustainable Product Development

When discussing sustainable product development, the concept of a circular economy is likely going to come up. In a circular economy, products are designed for re-use, repair, and/or re-manufacturing, rather than being designed to have a more linear product lifecycle. In a circular economy, recycling is a last resort action.

Today’s manufacturers are in a unique position to prioritize designing for sustainability, eco-design, and the circular economy. In fact, there are increasing expectations and requirements for companies to do just that. Whether pressure is coming from government regulations, investors, customers, or employees, there are more incentives than ever before for companies to lower their carbon footprint across the entire product lifecycle.

The good news is there are now more sophisticated tools to support companies in this effort. Generative design uses artificial intelligence to help designers innovate faster within the requirement restraints, producing lower weight designs and reducing overall material use. Simulation allows engineers to create (and stress test) products without any physical prototyping. With bill of materials (BOM) management in PLM systems, manufacturers can use this product data to automate and standardize sustainable processes and provide real-time insights.

There are other angles as well; the move to electric-powered vehicles (for personal and commercial use) is well publicized, but manufacturers could also lower emissions by considering the weight of the materials used to build some of the biggest greenhouse gas contributors: cars, boats, buses, planes, construction equipment, and more. This is more sustainable on several levels: less materials used in manufacturing, less fuel used (in shipping and routine use), less emissions, and the list goes on.

Putting Plans into Action

Passionate people at companies of all sizes are leading the efforts toward sustainable innovation. Many are outlining ambitious plans to do their part in this critical global effort.

Among them is Cummins. The largest independent supplier of diesel engines has an aggressive sustainability initiative – called Planet 2050 – includes quantifiable greenhouse gas reduction and sustainability goals for 2030, 2040, and 2050. On the 2030 roadmap is a goal of creating a circular lifecycle plan for every engine part that it designs and builds.

“This is designing for sustainability in action. This is designing with the circular economy in mind,” Kniker said, noting that it was inspiring to work with the Cummins engineering team because of their passionate drive to be a part of a solution to the global challenge.

“There is an opportunity in front of us for companies to go beyond the supplier-customer relationship and regard each other as true partners,” Kniker said. “A mutually beneficial dynamic that is better anchored in a greater mission. And as we consider these relationships in the future, we’ll want to prioritize ones that put the same level of focus and emphasis on this topic.”

When passion is combined with innovation, we can better address the problems we face – even problems as big and scary as climate change. Many of the tools necessary to turn the tide on climate change are already ready and available. However, it takes businesses and people ready and willing to use them to achieve a more sustainable future.