LiveWorx 2023: 6 Significant Ways Product Development Is Transforming

In 2023, the way products are designed, manufactured, and serviced is advancing faster than ever. The ways into which digital technologies are supporting companies that create products is more critical than ever.

Digital transformation is no longer just about getting to market faster with lower costs and higher quality, it has infiltrated nearly every effort to improve across large companies. There is a drive to re-shore, to make products more intelligent and factories more efficient, to build resilient supply chains, and to accelerate growth by complementing products with services.

In short, digital transformation – how companies use technology to fundamentally change how they operate and deliver products and services to their customers – is part of every facet of the business.

This is the backdrop to PTC LiveWorx 2023.

Back after four transformative years, the event kicked off in Boston’s innovation District on May 15. More than 6,500 attendees came from all over the world to not only learn the latest in digital transformation and PTC’s technologies, but also to be inspired.

To start the conference, PTC CEO Jim Heppelmann delivered a strong message: To accomplish sustainable transformation, companies need a digital transformation partner that not only has the powerful solutions necessary, but also is invested in customers’ success.

>>Watch the full version of Heppelmann's keynote on demand.<<

In the years between LiveWorx events, PTC has invested more than $3 billion in organic development and acquisitions to better serve customers and capitalize on the opportunities in the current marketplace. These investments include:

- Acquisitions of cloud-native solutions for CAD and PLM, Onshape and Arena

- Launch of PTC Atlas, the foundation of our SaaS platform strategy

- Launch of ThingWorx Digital Performance Management (DPM)

- Acquisition of Codebeamer, industry-leading application lifecycle management (ALM) software

- Acquisition of ServiceMax to anchor and augment our service lifecycle solutions

- Introduction of SaaS-based tools like Windchill+, Creo+, and Kepware+

At the heart of all PTC’s customers’ businesses, regardless of size, is products: how they’re designed, how they’re made, how they’re maintained, how they’re disposed.

With upgraded solutions and an expanded portfolio, PTC supports the product development lifecycle in new and deeper ways. As we enter a new age of products, Heppelmann urged companies to consider the following six ways product development is transforming—and how PTC is supporting these efforts for customers.

>>>It's not too late to join the LiveWorx livestream. Register for a free digital pass and get access to all the keynotes and track spotlight sessions.

1. Speed and agility

For many companies, speed is priority—and it trumps all else. They might be pioneering new market opportunities, startups bringing their first big product idea to market, or simply trying to compete in fast-moving markets, like retail.

These types of companies require tools that digitize the product development process, making it easy to collaborate with existing suppliers or to onboard new ones, to get their new products to market just in time.

Heppelmann brought forward three examples of companies using digital to accelerate time-to-market.

- Agility in the face of market changes: VF Corporation, a retail giant (think brands like The North Face, Vans, Timberland), has digitized its product development, building in more agility that allows them to respond to market changes based on data. With a central repository in Windchill FlexPLM for all product information and communication, they’re able to collaborate with vendors, adjust timelines, and make smarter decisions.

- Traceability and speed with agile software development practices: Festo, a leader in factory automation, is seeing software play a more important role in their products than ever before. They’ve adopted modern Agile software development practices—scrum teams, sprints, Kanban boards and more—as well as tools like Codebeamer ALM to support this way of working. Connecting ALM with PLM, they’ve been able to gain clear traceability throughout the development process.

- Agile for hardware development: Develop hardware like software? It’s possible, with the right tools and process adaptations. Ocado Group, a large online grocery retailer, is using Agile in the development of their grocery-picking robots. Using Onshape’s unique features like branching and merging, as well as real-time collaboration capabilities, they’ve been able to innovate faster, enable feedback loops, and bring new iterations to life on shorter timetables.

2. Pursuing profitability with the digital thread

Companies that already have a broad portfolio of products on the market must balance growth with profitability, which means, Heppelmann said, speed must be balanced with efficiency.

“When product information is reused, and versions and configurations linked together in a way that provides traceability and change control, we call it a model-based digital thread,” Heppelmann said.

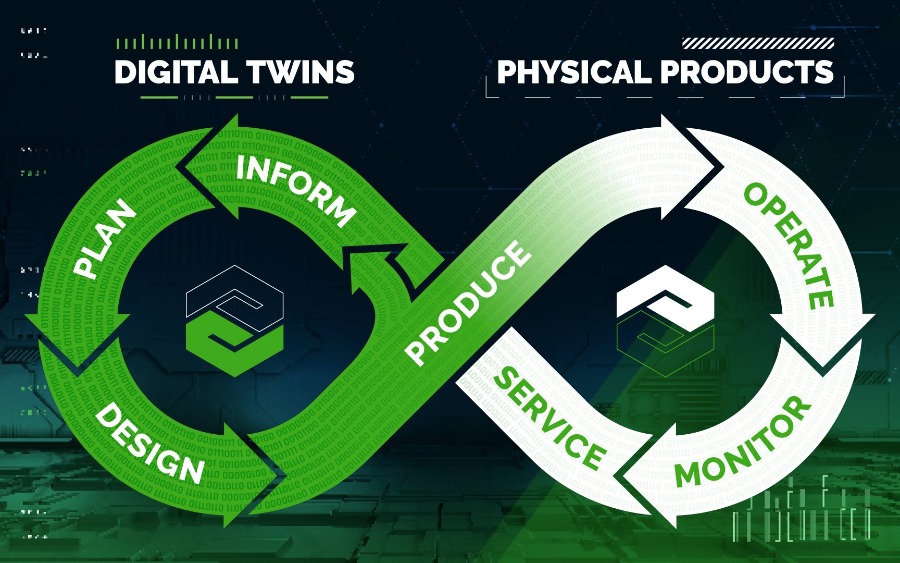

The above infinity diagram illustrates the concept of a model-based digital thread connecting its way from the digital world to the physical world and back again following the lifecycle of a company’s product.

It starts in the digital world with planning and requirements and system engineering, which then leads to engineering, testing, and validation of the product concept, and ultimately to the manufacturing process that converts the digital product concept into a physical product.

Then the end customer takes delivery of and operates that product in the physical world. Meanwhile the manufacturer monitors the product to ensure it is delivering full value, and provides service and support whenever it is not.

Along the way, much is learned, and this closed-loop feedback informs problem reports and engineering change orders that lead to improvements in the product design and manufacturing processes. Then, the process starts again with a new and better model or version of the product.

PTC customer Volvo Group is embodying this model-based digital thread and integrating it into their product platform strategy, Heppelmann shared. Given its extensive vehicle portfolio, which ranges from cars to trucks to construction vehicles, including electric options, they need to reuse many of their parts (engines, chassis, axles, etc.) across their product lines. In this way they reuse factory lines, driving efficiency while still expanding the number of products.

In a video, Silvi Laks, SVP Vehicle Engineering at Volvo Group, said the company depends on efficient PLM tools that can both store product information but also support global collaboration. “I would say that the collaboration tools, the visualization tools, the simulation tools are really important,” Laks said.

In using PTC’s CAD and PLM systems (Creo and Windchill), she said Volvo has “reduced the amount of complexity by using this methodology and we have actually seen that even if we have increased the number of products, we have reduced the number of parts by a lot.”

3. Asset-centric vision

The recent acquisition of ServiceMax allows PTC to complete the vision for a closed-loop model-based digital thread across the full product lifecycle.

“ServiceMax enables PTC to bring this full infinity loop to life,” Heppelmann said, underscoring the incredible value—and potential for growth in the service side of the product lifecycle. He noted the product can generate 10 times more service revenue over its life than it did through the initial product sale.

“Many companies have products installed all over the world, and some employ an order of magnitude more service technicians than engineers. Service isn’t an afterthought – it is a big part of the business,” he said.

With the addition of ServiceMax to PTC’s existing Service Lifecycle Management (SLM) suite, which includes Arbortext, Servigistics, ThingWorx, and Vuforia, the vision is to develop an asset-centric model unique in the industry and critical to servicing complex products with different configurations.

Neil Barua, former CEO of ServiceMax, and now President of the Service Lifecycle Management (SLM) business, echoed the sentiments. “Aligning the product and service parts of the PTC portfolio creates new superpowers for our customers…We call this an asset-centric vision because the as-maintained asset definition acts as the hub, serving as the integration point that pulls together all the powerful capabilities of the spokes.”

Barua offered details on how this integration will work and the value it will bring to companies across the service lifecycle:

- Windchill provides access to the initial Service Bill of Material for each new product, along with a detailed 3D digital twin.

- ServiceMax manages the as-maintained record of the installed base, including which customers own which products, and what their contractual service entitlements are. It handles all the field service managements activities as well, such as scheduling and dispatching field technicians.

- ThingWorx IoT enables monitoring of the product fleet, to enable service to be more predictive and preventative, and done remotely in many cases.

- Arbortext can deliver technical service documentation, such as parts catalogs and work instructions specific to the asset.

- Vuforia enables service technicians or end customers to see 3D service instructions augmented right onto the product.

- Servigistics can further optimize spare part costs, saving customers money by reducing spare part inventories to the minimum level necessary to meet service level agreements.

“This strategy – made possible by combining the strengths of PTC and ServiceMax – ushers in the era of a service organization that is predictive and remote-first, resource optimized, customer-focused, and most importantly commercially sustainable,” Barua said.

4. Focus on sustainability

Like with cost drivers, it is estimated that 80% of a product’s environmental footprint is committed by engineering decisions made while the product is being designed. After those decisions are final, you are stuck with the result.

“To make meaningful changes to your company’s environmental footprint, then, you have to affect decisions made in the digital world in order to drive better outcomes later in the physical world,” Heppelmann said.

Catherine Kniker, PTC’s Chief Sustainability Officer, announced two expanded relationships to support and enhance sustainability efforts for customers.

First, PTC is expanding its relationship with Ansys by integrating their materials management system with Creo and Windchill; engineers can see pre-approved materials options directly in those systems.

“Doing this all in a single system will help engineers balance performance and environmental priorities as they design products,” Kniker said.

Second, PTC is advancing our relationship with aPriori as well. By using aPriori’s cost, manufacturability, and sustainability assessment capabilities in Creo and Windchill engineers can understand the implied manufacturing footprints and costs of their designs.

In recognition of the importance and urgency of sustainability and reducing greenhouse gas emissions, PTC has signed the Science-Based Target initiative commitment for short and long-term greenhouse gas reductions.

Sustainability represents just one part of the regulatory compliance companies are responsible for. For industries like automotive and medical device with safety-critical devices and software, PTC supports standards like ISO-26262 and automotive Spice, FDA or similar global regulations. Institutionalizing compliance with a suite of solutions, like Codebeamer, ServiceMax, Windchill, Arena, ensures companies meet this critical part of the product development process, Heppelmann said.

5. Transition to SaaS

Starting in 2019 with the acquisition of Onshape, PTC has continued to make big moves toward a SaaS model across all our products.

“If you want to digitally transform your business to capitalize on the strategies I’ve been discussing today, and you want to do it in the easiest, fastest, and most efficient way, then you will ultimately want PTC’s powerful technology delivered to you as a service,” Heppelmann told the audience.

Over the next few years, PTC will continue to bring SaaS to life across all our digital thread products through our ‘Plus Strategy.’ Windchill+, Kepware+ are already available—and Creo+ launched at LiveWorx.

One of the most exciting capabilities of Creo+ is dynamic, real-time, multi-user collaboration. Engineers across the globe can simultaneously work on a single design, review each other’s changes, branch designs to evaluate possible changes, and selectively merge what they want back together. It is just one of many advantages of going SaaS.

Learn more about our SaaS strategy.

Learn more about Creo 10 and Creo+.

6. Powerful partnerships

Joined on stage by Ansys CEO Ajei Gopal, Heppelmann shared the multiple efforts where PTC and Ansys are collaborating and co-developing.

“Our relationship has thrived over the past few years for one key reason – we take a customer-centric view, solving complex problems across industries and around the world,” Gopal said. “I believe PTC and Ansys have only scratched the surface of what we can do together to benefit customers.”

Since announcing a strategic partnership in 2018, Ansys’s simulation technology has been embedded into Creo, with more innovations built into Creo 10. Then, the relationship expanded to include PLM and simulation process data management through Windchill and Ansys Minerva.

As mentioned previously, the partnership is expanding again to extend Windchill’s capabilities for materials management and sustainability with Ansys Granta, the premier materials data and management system, to help customers understand the impact of materials choices.

Both CEOs shared their passion for “an open approach” that will have long-lasting and transformative impacts on how their customers develop products. Both companies will be doing more within the cloud in Onshape, Creo+ and more.

“All these strategies fundamentally shift decision making to the left – earlier in the product design process – so our joint customers can leverage insight-driven design faster and accelerate time to market while improving product quality,” Gopal said.

Heppelmann agreed. “We want to meet customers where they are and help them evolve to where they want to be in the future.”

‘We can help’

As Heppelmann’s keynote came to a close, he left this audience with a single message: PTC can help.

Companies are turning to PTC because of our portfolio of digital technologies, extensive partner network, and industry expertise. Together our software supports each stage of the product lifecycle and is further differentiated with our SaaS and cloud-native offerings.

If your company has a need for speed and is employing Agile methodologies, PTC can help.

If you’re part of an established company balancing growth and profitability, PTC can help.

If sustainability, compliance, and SaaS are top of mind, PTC can help.

“I hope to leave you with the sense that these may be the ‘golden days’ in the product lifecycle world,” Heppelmann said. “We are together at the front lines of where businesses are being transformed and value is being created.”

Stay tuned for additional PTC LiveWorx 2023 recaps on the blog, sign up for a digital pass, or keep up with the happenings on Twitter.