Getting Started with ThingWorx Analytics

The Industrial Internet of Things (IIoT) gives insight into how manufacturing equipment and processes are performing through smart, connected devices. IIoT generates data that can be analyzed and used to optimize results. However, managing and analyzing this data can be complex and time consuming.

ThingWorx is a complete, end-to-end technology platform designed for the IIoT. It delivers tools and technologies that simplify data collection and analysis, empowering businesses to generate improved outcomes. ThingWorx Analytics is designed to specifically tackle the volume, velocity, and variety of data generated on the shop floor.

Recently, we sat down with PTC University Technical Instructor, Bernd Deinert, to hear what students gain from PTC University’s ThingWorx courses. He specifically spoke about the ThingWorx: Fundamentals of Analytics course and how it’s being used to analyze data and enable organizations to identify the factors that are influencing outcomes most.

Keep reading to find out what Bernd shared about ThingWorx Analytics.

Thank you for meeting with us today, Bernd. To start, can you share a little bit about ThingWorx and how you started teaching ThingWorx training courses?

For a long time, I trained our global customers with PTC software products in the area of requirements, testing, and software code and configuration change management (Windchill RV&S). It was exciting to visualize this data together with our ThingWorx product data and to make that visualization more easily accessible. I found this work very interesting and started specializing in ThingWorx, as well as Windchill RV&S, seven years ago.

ThingWorx is a software used to visualize data coming from smart, connected products. For example, many types of devices are used in manufacturing processes: conveyor belts, chemical reactors, vessels, robot arms, sensors, and more. Nearly all of the devices on the shop floor can be set up to generate data. Connecting these devices and collecting their data in a centralized place results in an Internet of Things (IoT). The ThingWorx platform provides a way to organize and visualize the data that’s being generated. For example, ThingWorx can be used to create dashboards that display things like performance statistics.

Can you talk a bit about one of your favorite ThingWorx courses to teach?

I really enjoy teaching the ThingWorx: Fundamentals of Analytics course. In this course, I can show how, with just a few steps, it’s possible to analyze production processes with the ThingWorx Analytics Extension. Once analyzed, those processes can be better understood and optimized. This can lead to an increase of the OEE (Overall Equipment Effectiveness) value.

In the three-hour course, we spend some time looking at analytics theory and immediately apply those theories in interesting exercises.

Is there a certain real-world example that’s used for the course’s exercises?

Our exercises are all based around using ThingWorx to analyze and optimize a Printed Circuit Board (PCB) manufacturing line. As part of the PCB assembly line, we look at data coming from things like a solder paste machine, pick and place machine, and a reflow oven.

That sounds interesting. Taking a step back, can you explain a bit more about how analytics works in the context of smart, connected products? For example, the solder paste machine, pick and place machine, and reflow oven you said you use in course exercises.

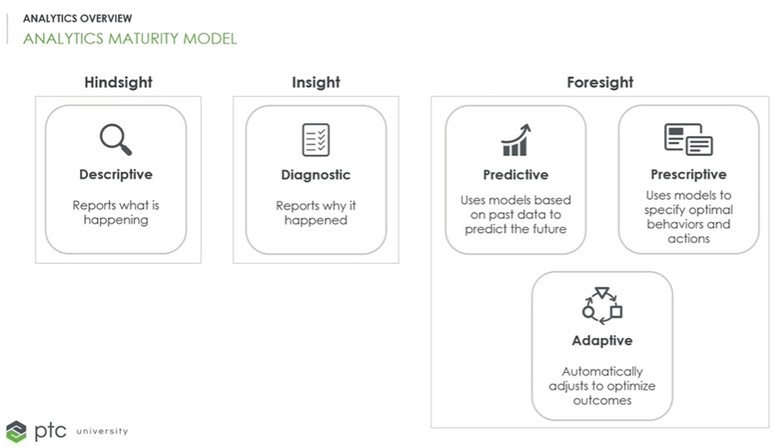

Sure, to explain this I’m going to walk through the Analytics Maturity Model, and this is something I also cover in the course when I’m explaining the theory of analytics.

With ThingWorx Analytics, data can be collected from various types of devices with different connectivity. This information is then used as a data set for ThingWorx tracking. The first step is to find hot spots. If you have a signal, it tells you that there might be a correlation between these data sets, and they should be analyzed more closely. Other cold spot data can now be excluded for further analysis.

Any correlations that are uncovered can be used to make predictions. For example, there might be a correlation between temperature and pressure. Therefore, if a certain temperature is observed, the pressure can be predicted based on a mathematical model approach ThingWorx will create. Finally, this mathematical model can now be used to predict future behaviors of the devices and to take action before damage occurs to devices. This allows us to optimize production processes.

Here's a diagram showing how those steps look together:

Thank you for explaining that. So, jumping back to when you described the course exercises, after setting the stage with the Analytics Maturity Model, which you just explained, the exercises give students a chance to apply those steps to the real example of a PCB manufacturing line?

That’s correct, and the ultimate goal is to get to the adaptive analytics stage where a machine learning algorithm can be uncovered. That’s when the machine begins to learn from itself and produce improved business outcomes, supported by ThingWorx Analytics.

One final question: What do you like best about teaching PTCU courses?

I aim for my courses to be like opening a door for students. For example, opening a door to understanding and beginning to use analytics. At the end of the analytics course, I ask students if they’re able to explain to another person or colleague, “What is analytics?” Analytics is a big science and our course is foundational—there could be an advanced analytics course at some point—so if a student begins to understand what analytics is and how it works, then I’ve been successful as an instructor.

Take a PTC University Course!

Are you ready to enroll in the three-hourThingWorx: Fundamentals of Analytics coursewith Bernd Deinert? A PTC University LEARN Online Subscription allows you to take an unlimited number of half-day public classes virtually, from any location. The subscription also includes two certification attempts. Learn more now.