On the Digital Thread Trail

This post was initially written by guest author Andreas Kratz, Head of Business Development and Sales DACH at Transition Technologies PSC GmbH; it has been translated from German to English.

Information from the different systems in a company is like clues in a criminal case. Each clue contains data. Some clues are lost due to missing documentation. Others may only provide the decisive information to solve the case in connection with other data. It is, therefore, essential to combine, evaluate and make all information from all tracks visible. This is the only way to gain the right insights and make decisions. There is valuable data in every company. This data often remains undetected or only known in part in different areas. If a company is looking for clues, the question arises as to which is the right tool in connection with the right methodology.

The Digital Thread at Schaeffler

Schaeffler, one of the world's leading automotive and industrial suppliers, would like to combine these individual "clues" into a significant whole. The company's goal is to establish an integrated, agile, and end-to-end IT landscape for developers while simultaneously implementing the obligation to provide evidence of testing and measurement procedures in the automotive industry along the entire product life cycle.

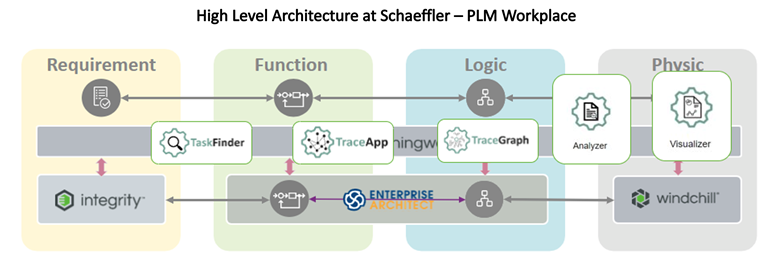

Existing data, distributed in a heterogeneous system landscape, should be merged and made readable and transparently available across systems.

A connected PLM solution was set up on the basis of ThingWorx. Information from all main memories and silos was brought together in this way and the foundation for the digital thread was created. The systems were integrated according to the OSLC methodology, allowing the applications to link and share data and create, request, update, and delete operations without copying. The documentation of all information is thus guaranteed. The challenge here was the different OSLC capabilities of the systems.

The goal of bringing all information together was to establish a digital thread and ensure the flow of information from central memory banks, silos, suppliers, and OEMs with integrity in the collaboration across all areas.

The new capabilities gained with product-technical networking were integrated into processes and workflows in Schaeffler's IT landscape. Schaeffler is, therefore, able to share information faster and more effectively.

However, the "search for clues" at Schaeffler does not end there. More on organizational networking and networking within the supply chain will follow and Schaeffler remains excited to bring together more information across their PLM-enabled digital thread.