3 Benefits of Augmented Reality in Manufacturing

In uncertain economic times, companies may feel compelled to pause technology investments. However, that tactic is likely a mistake when it comes to augmented reality (AR), a visualization technology that uses computer vision software running on smartphones, tablets, and headsets to “augment” a worker’s environment. AR is built for the current issues many industries face in their pursuit of key sustainability goals. These challenges include an employee skills gap, outdated tools, products that are increasingly complex, and greater customer demands on production.

What are the benefits of augmented reality in manufacturing?

Better training and upskilling

One of the critical challenges many industrial verticals must contend with is talent acquisition and retention. The current economic landscape has made this issue even more fraught as organizations wrestle with hiring slowdowns or freezes despite the fact that they still need skilled workers, and the ones they have are often saddled with outdated processes and tools. AR helps address these challenges in several ways. A primary use case of AR is for training new hires or upskilling existing employees by using interactive visual guides that enhance learning and retention, shortening the time it takes for a person to ramp into a new role. Often, these training modules are created through user-friendly AR expert capture capabilities, allowing seasoned employees to share their institutional knowledge quickly and seamlessly.

Increasing on-the-job efficiency

AR’s benefits don’t end with training. With the right AR software, employees can increase their on-the-job efficiency by leveraging the technology to deal with complex problems and processes. AR makes it possible for employees to access step-by-step digital instructions, instructional videos, blueprints, and more. These digital assets can dramatically improve the employee’s ability to get the job done more quickly and efficiently while eliminating errors because the instructions are in context to the machine they’re working on. Instead of trying to translate instructions from paper, they’re learning by doing. These are key requirements across all industry verticals but are particularly important in the areas of field service and discrete manufacturing.

Remote experts can drive problem solving

If an employee runs into a problem they can’t solve alone, AR allows them to connect to a remote expert who can help. AR can show an off-site expert what the person sees in front of them, making it possible to solve issues on the spot. Remote collaboration remains a crucial use case among AR adopters because it helps new employees become more proficient, eliminates the cost and time associated with sending out a second person, and makes it possible for companies to better utilize their most knowledgeable and seasoned employees by making them widely available to more people.

AR’s ability to drive efficient remote collaboration does more than speed the time to completion of critical jobs. It can dramatically enhance a company’s drive toward increased sustainability. Whenever an expert can avoid an additional truck roll or an airline flight to a remote location, the company saves money and decreases its carbon footprint. As organizations get serious about their environmental, social, and governance (ESG) goals, AR can play a primary role in reaching them.

Many companies already have a wealth of digital assets in the form of CAD data that they can leverage to begin the process of building out AR capabilities and experiences. With careful planning, they can link these AR applications to their product lifecycle management (PLM) software to ensure employees always have the most current product data and instructions.

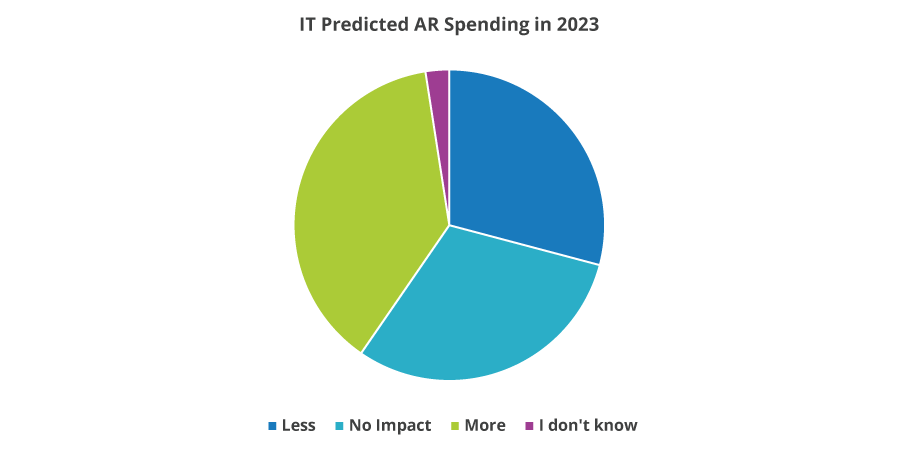

Source: IDC, 2023

Planning beyond the downturn

Most forward-thinking industry verticals are already looking past the current challenging economic times toward the next era of growth. They know that investment in new technologies today will position them well for future growth when the rebound arrives. Companies that put off investments in technologies such as AR not only postpone the immediate benefits but also cede the possibility of building a competitive advantage they can exploit once things heat up again.

A recent worldwide IDC survey showed that improved environmental sustainability was the number one business priority among IT and business line executives across a wide swath of industry verticals, including construction, energy, discrete and process manufacturing, healthcare, life sciences, and more. Improved efficiency and reduced business risk followed close behind. AR is uniquely suited to address these and other priorities.

As a result, it should come as little surprise that IDC’s Augmented and Virtual Reality Spending Guide predicts sizeable growth in industry spending on AR in the coming years despite recent recessionary concerns. The November 2022 forecast shows commercial spending on AR across hardware, software, and services is set to grow from $4 billion in 2022 to over $5 billion in 2023, on its way to $8.7 billion in 2025.

The appetite for AR technologies is increasing despite existing economic concerns. AR’s ability to address a wide range of current and future challenges is very compelling to forward-thinking companies. From employee training and upskilling to driving increased efficiency and fewer errors to enhancing remote collaboration and improving sustainability, your company should consider AR today.