The Creo Base Package Additive Manufacturing Tools You Didn’t Know You Had

You might be aware that PTC CAD extensions provide you with functionality that supports 3D printing. These extensions allow you to carry out advanced tasks such as the following:

- Configure lattice structures in your part models.

- Automatically position and optimize orientation of parts on the print tray.

- Nest parts in your print tray assemblies.

- Save and modify your print tray assemblies.

But did you know that Creo Parametric provides you with additive manufacturing capabilities in the base package?

Let’s take a closer look:

Interoperability to 3D Printers

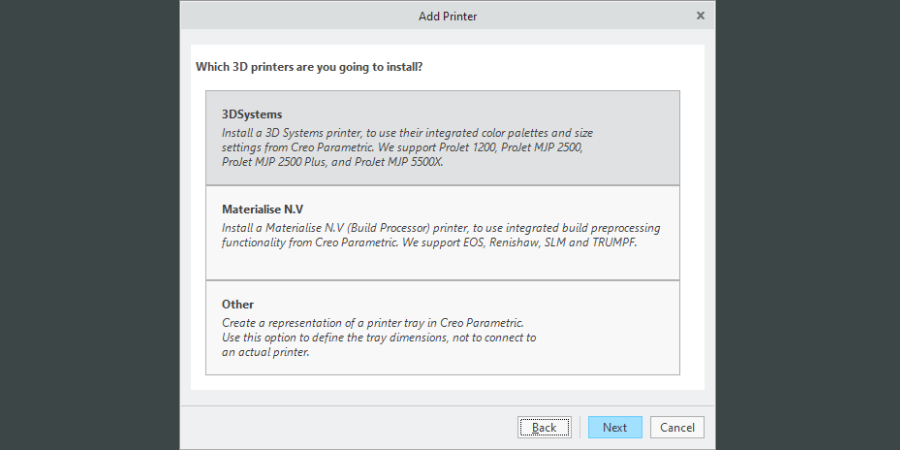

Creo Parametric supports interoperability with a variety of plastic printers, including those from i.Materialise and 3D Systems.

Within Creo Parametric’s options dialog box, you can set up connection to these printers, as well as a generic printer or a Windows 10 printer, using a URL or IP address.

Image: Simple interface for connecting a 3D printer.

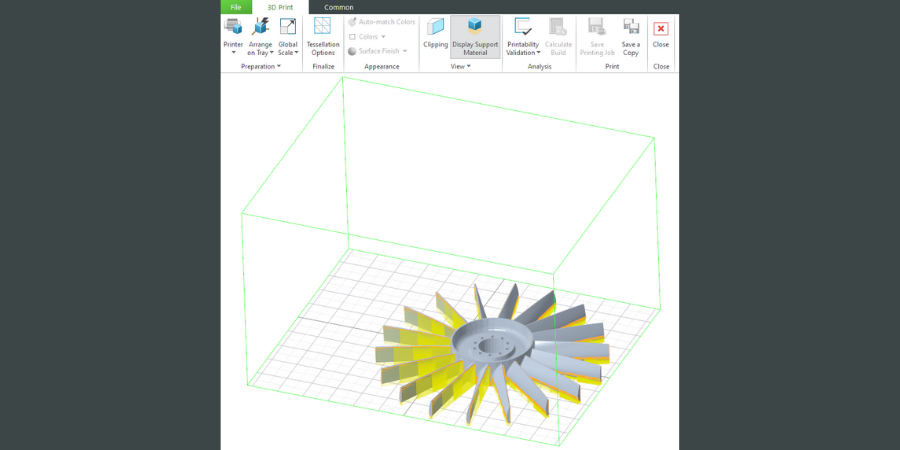

With 3D Systems integration, you can also assign materials and colors as well as calculating the build and building material. You can even display the necessary support material from the 3D Print interface.

Image: Object arranged in print tray in Creo Parametric.

Print Check

Within the 3D Print command in Creo Parametric, users have access to two different kinds of Print Checking that can be performed with out-of-the-box functionality:

- Validate Thin Walls: This will allow you to see where your part geometry is so thin that it might break during printing or during the removal of support structures.

- Validate Narrow Gaps: You can check where features such as holes and extrudes have resulted in gaps in the geometry that are too small to print correctly.

Performing these checks can save you time, effort, and frustration by identifying early where you need to fix your model to support Additive Manufacturing methods.

The Additive Manufacturing Extension supports additional checks including Lattice Penetration and Global Interference.

Order 3D Prints

Some product development organizations are not ready to invest in the move to 3D. You might not yet have the infrastructure or budget to support additive manufacturing in your factory. Or maybe you plan to produce in quantity with more traditional subtractive manufacturing methods, but you want to obtain a prototype quickly and inexpensively.

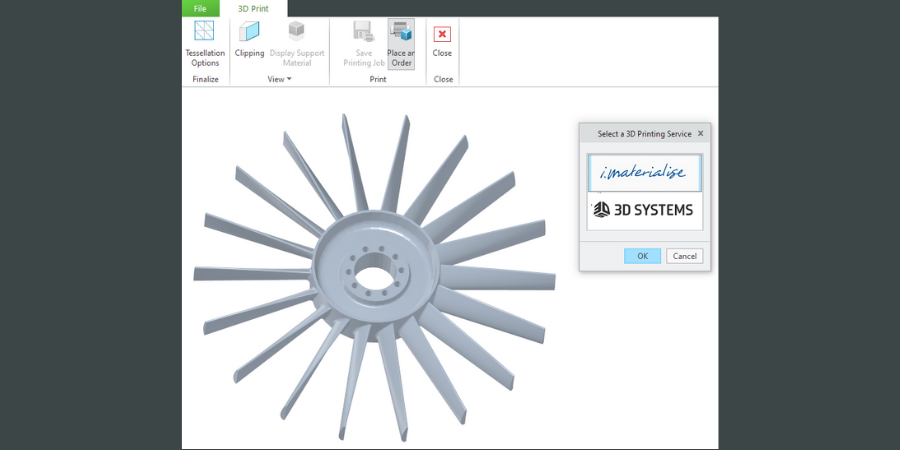

PTC has partnered with the i.materialise and 3D Systems Print Bureaus so that you can have parts printed for you. You can request quotations directly from Creo Parametric.

Image: Ordering quotes from Print Bureaus from directly within Creo.

Then if you decide to move forward, you can order your 3D printed parts to have them delivered. These 3D printing services help lower the barrier to entry and allow you to explore the right options for you.

Get Started Today

Since Creo Parametric provides you with the ability to validate your models, print directly to a printer, or send your models out, you can start taking advantage of the power and benefits of additive manufacturing immediately.