A Beginner’s Guide to Generative Design

Editor's Note: This post was originally published in 2017, it was updated in January 2023.

Generative design revolutionizes products and the way they’re made. Drawing on cloud computing and artificial intelligence (AI), generative design creates optimized models that are different than what standard engineering processes come up with. How exactly? Read on to learn the basics.

What is generative design?

Generative design is a technology in which 3D models are created and optimized by cloud computing and AI. A user sets up requirements for the model, such as manufacturing processes, loads, and constraints, and then the software offers designs that meet those requirements.

Image: This GE bracket redesign was 75 percent lighter than the original design and optimized to stay within the material yield stress using generative design.

That doesn't mean the designer is off the hook when it comes to engineering a product. The human in this scenario still needs to think about weight limits, physical constraints, availability of materials, and so on. In fact, the better the engineer defines these different criteria, the better the system can discover possible solutions. Generative design can add a lot of value to engineers’ work while taking significantly less time and reducing human bias. It produces multiple solutions simultaneously, all satisfying the given requirements, using the power of cloud computing.

Fortunately, especially for novices, the software can help them explore constraints, too. For example, you could set up a design for 3D printing and then try again with 3-axis milling. From there, you can decide which results best suit your budget, time schedule, etc., and set that as the optimal solution moving forward.

What problems does generative design solve?

Generative design yields hundreds of innovative design options in a short time—especially if the software is tapping the cloud for computing resources.

It's then up to the designer to evaluate tradeoffs. For example, even though two models meet specifications, option one might be lighter weight, while option two is slightly stronger. Both options work, but having more choices and the ability to prioritize features is always preferable.

Perhaps the largest benefit is that generative design brings innovative products to market in record time. When being used most efficiently, generative design will help improve your current processes and design outcomes in less time overall. As a continuous improvement activity, generative design can help you take existing designs and optimize them for your needs. It can serve as a valuable asset during design for both new and existing parts, innovating the work you already do.

Generative design also makes a significant difference to companies that want:

- Product differentiation. Let's be honest, most designs are based on models that worked before. We make incremental changes and hope it's attractive to customers. Generative design allows you to break out of that rut by creating high-performing new parts and products that exceed requirements. Plus, they’re not easily duplicated by the competition.

- Expert results (even from novice engineers). Concerned about the skills gap? An entry-level mechanical engineer can now create a part using generative design without extensive knowledge. And when the system returns hundreds of suitable solutions, artificial intelligence, included with generative design technology, can quickly help filter myriad design options.

- Optimized product costs. Generative design can save money by rooting out over-designed parts. These are designs that, while reliable, may use more materials or complex manufacturing methods than necessary.

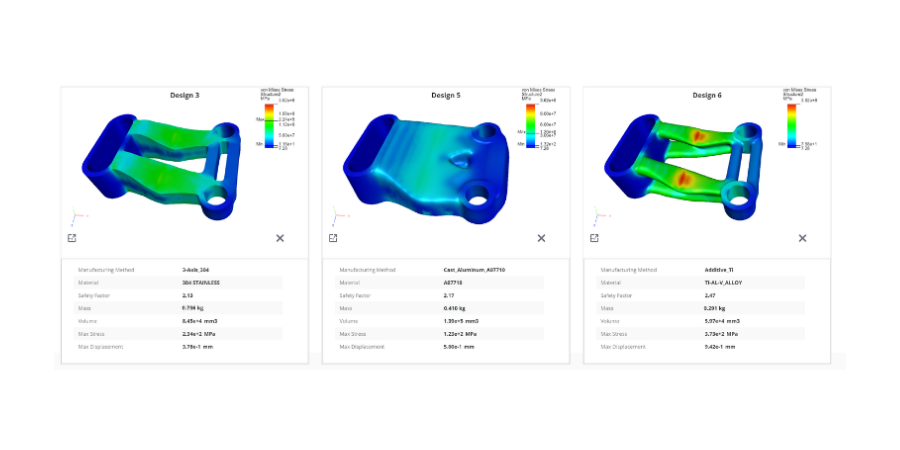

- Optimized reliability. Carry out stress analyses on the generative design results to validate the quality and durability of the designs. This ensures your design works in the real world. (It also saves costs in manufacturing and service support.)

Image: A part generated for 3-axis milling, casting, and additive manufacturing.

See Generative Design in Action

What does it look like when a generative design is leveraged? See how a study might be set up and a part optimized in this video:

How is topology optimization different than generative design?

It's helpful to understand the difference between generative design and topology optimization, because the two terms are often used interchangeably. From PTC's perspective, topology optimization converges on a single solution based only on functional objectives, constraints, and loads. Generative design evolves multiple solutions simultaneously to converge on the best possible set of solutions based on functional and non-engineering requirements. Read more here.

What does generative design mean for today's engineers?

We mentioned that entry-level engineers get a professional boost with generative design, since they can quickly start producing successful generative models. Generative design allows engineers at any level to produce increasingly excellent work, meeting—or surpassing—expectations in less time. Getting that time back provides engineers the freedom to better understand how to improve designs and solve use cases not by focusing on parts, but by understanding the entire system and being able to redefine the requirements of specific parts to optimize the result of the whole.

Going Forward with Generative Design

We hope this answered some of your questions about generative design and the seemingly alien models it creates. In short, it’s simply a new, but powerful, technology to help companies deliver their best designs in less time.