The Best Practical Digital Twin Use Cases

When looking to fully understand digital twin, or really any aspect of digital transformation (DX), it is important not to get lost in academia. The reality is that we live in innovative times with an accelerating pace of technological development and frequent market disruptions, large and small.

Thankfully, there is no shortage of experts expounding on “the possibilities” of new technology X or “the potential” of new technology Y. What can be in short supply, however, is an explanation of realistic, practical application.

The reality is that there are many, many expanding frontiers of DX strategy and technology, but not all are equal. Certain technology can positively impact the bottom line today while other ideas still need the right market conditions to be scalable and fully impactful. Thankfully, digital twins are squarely in the former category.

Organizations considering digital twin implementation should not restrict themselves to a purely conceptual approach. Looking at specific use cases will strengthen the case that digital twins are worth the cost of investment, especially if deployed methodically and with a guiding DX roadmap.

Before we can fully explore exactly how digital twins are helping, however, it is essential to understand what exactly they are.

Understanding Today’s Digital Twin Potential

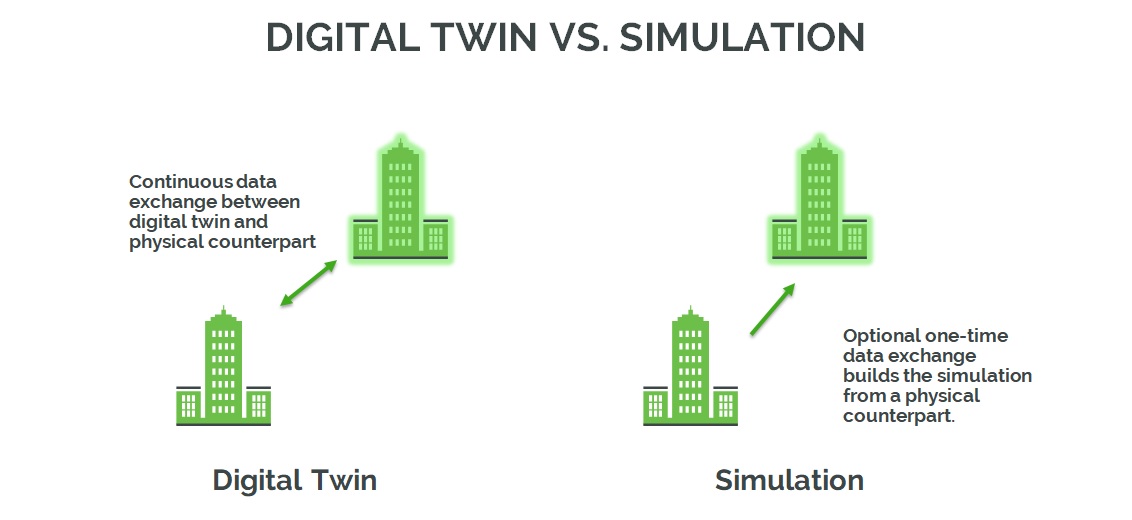

There is a lot of confusion surrounding digital twins and simulations, with the latter often mistakenly used as a synonym to the former. So, while a simulation can mirror a physical process, place, person, or product – it never once measures this counterpart. For example, it is very possible to simulate New York City’s traffic map: routes, lights, signs, buildings, crosswalks – everything. If, however, a massive sink hole opens up and traffic has to be re-routed, the simulation will not reflect this. It is an unanchored digital representation of a physical location but without the constant measuring and reflecting that goes on in a digital twin. Digital twins can only exist if they have something physical to be a twin of. Simulations do not necessarily need any real-world counterpart.

Digital Twin Use Cases in Engineering

Case in point, I have read numerous “use cases” in recent days that discuss how digital twin reduces the cost of prototyping and product testing via the use of a digitally simulated version. This simulated version is just that, and not a twin. Digital twins in engineering only really assist engineers once their products have entered the field. Once deployed, data from various in-use products are gathered and used to highlight surprise strengths or weaknesses in product quality, as well as provide insight into overall usage.

Industry Example: Digital Twins in the Automotive Industry

One use case that we highlighted in our newly released white paper involves automotive engineers. Say a new line of cars has just been released and each one has a digital twin. Over time, the engineering team observes a consistent weakness occurring in the tire suspension system: one component in particular is wearing out significantly faster than anticipated. Given the severity of the issue, different actions can be taken. If spotted early enough, a simple software patch may be all that is needed until the vehicle can be returned for service – one that redirects pressure away from the component and distributes it elsewhere in the suspension system.

Recalls are costly ordeals in more ways than one. Not only does the automotive maker have to deal with the costs associated in the repairs, but reputation can also take a hit – especially if the recall is large enough for a media outlet to notice. Finding the problem earlier often reduces the nature of the work needed and can limit the recall, stopping a big problem while it’s still a small one.

Digital Twin Use Cases in Manufacturing

When considering how digital twins can help your manufacturing, a key word to remember is visibility. Organizations, especially larger, international ones, can sometimes struggle to know what exactly is happening on the ground floor. Creating digital twins of manufacturing processes perhaps provides the most complete answer ever – more than any human could be reasonably expected to see or know at any given time.

In this case, the data is often related to operational efficiency. How well is this machine performing? Is the workload being evenly distributed? If not – where is the bottleneck? How is the hardware handling the bottleneck? Digital twins in manufacturing make predictive maintenance not only possible but expected. Overseers know where the flaws in the system are and, in most cases, can correct them before they cause a major disruption like downtime.

For a further example of how digital twins can improve product and process efficiency, please watch this video from Ansys and PTC:

Industry Example: Digital Twins in Logistics

While much of the focus on process digital twins is in manufacturing, it is important to remember that our economy operates on increasingly complex systems. One such industry at the center of acceleration and innovation right now is logistics. The COVID-19 pandemic accelerated the trend away from retail-based operations and toward a shipping economy. With companies looking to get ahead, information can be a key differentiator. Shipping is a complex process and utilizing digital twins allows organizations to see where they could be faster, more eco-friendly, and better secured.

Digital Twin Use Cases in Service Lifecycle Management

Data is key to how well many of us perform our functions, and this is certainly true in repair and maintenance. Technicians with access to a product’s digital twin have a clear window into exactly how the product was used, when, and can often tell even by who. Knowing this information drastically improves the potential for first-time success rates. That said, this is not the only way digital twins can optimize a product’s service lifecycle.

By knowing exactly how their products are used, and having better insight into how customers use them, it becomes possible for companies to identify opportunities they just couldn’t see before. Let’s look at Celli, an equipment provider in the beverage industry. Celli used to just sell its drink dispense systems to its clients, focusing on quality and ease of use. As it got more use data, however, the company quickly realized it could do more. By knowing what customers were buying, Celli could sell this insight to its clients, giving a new level of service and creating a completely new revenue stream.

Industry Example: Digital Twin in Healthcare

Much of this article has focused on digital twin technology in the here and now, and there is certainly no shortage of use cases to be found in the healthcare sector, whether it is in monitoring equipment status or tracking patient intake. That said, digital twin’s true potential in the healthcare sector is still a work in progress, with only the initial results readily available to the public. If you’ve ever worn a Fitbit or any smartwatch with a body sensor then congratulations: You’re participating in the first ever, very incomplete, digital twins of us.

It is expected that, one day, internet of body technology will improve to the point that every individual can have a digital twin created, one that measures their exact physiology and has a complete medical history. Such information, readily available and consistently updated, will open doors to levels of personalized care not currently possible – or at least not scalable – in the current system.

Digital Twins: Practical Now and Primed for the Future

Digital twins are not abstract concepts of digital transformation. They are practical, here-and-now solutions that will only improve as data collection and IoT technology continue to innovate. These use cases should be seen as a window, rather than an exhaustive list, into their capabilities.