Designing for Sustainability: How Cummins Optimizes Product Designs for the Environment

Introduction to Cummins and PLANET 2050

As a global leader in social and environmental responsibility, Cummins is committed to doing their part to create a more sustainable, prosperous world. That is why Cummins launched PLANET 2050, an aggressive sustainability strategy that has long-term aspirations, but by 2030 includes significant milestones such as:

- Reducing absolute greenhouse gas emissions from facilities and operations by 50%

- Creating a circular lifecycle plan for every part

- Generating 25% less waste in facilities and operations

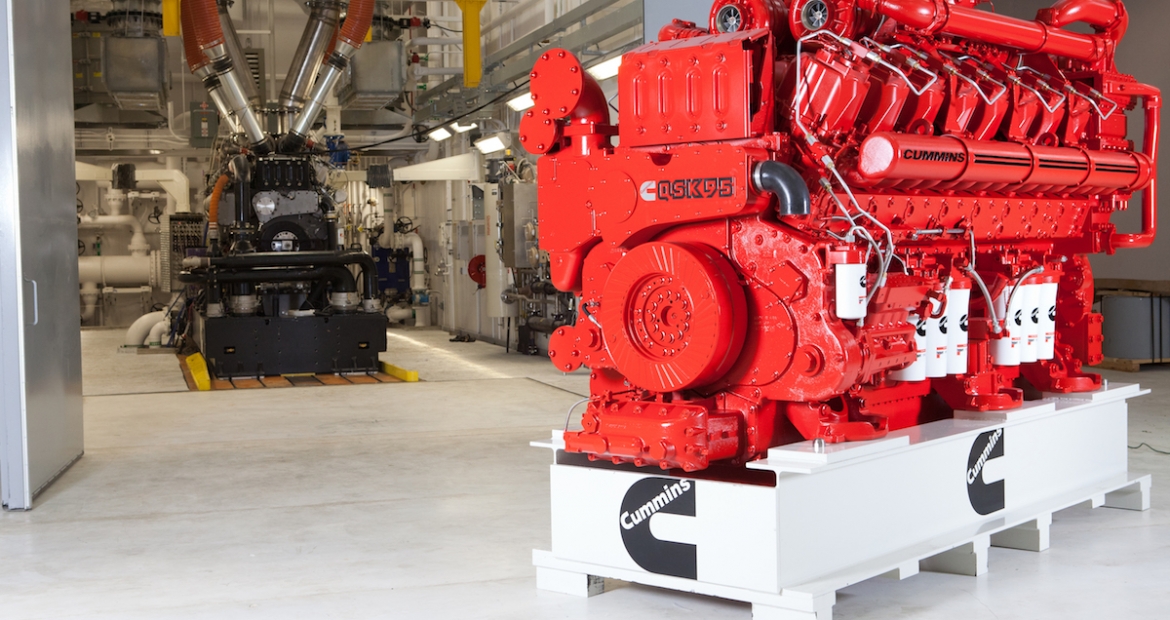

The goals Cummins has set are ambitious, especially given that the business produces more than one million end-user engine products per year. Such a large production output requires a significant amount of material and natural resources, as well as compliance with environmental regulations. Also, unlike other power systems, certain Cummins products are designed to be used for longer than 25 years (or more than 120,000 hours) of rigorous operation. Cummins’ power systems go through multiple rebuilds to achieve such longevity, emphasizing the importance of considering sustainability over a product’s lifecycle.

With sustainability in focus, Cummins set out to rethink the processes it uses to design its internal combustion and fuel cell engine systems. About 70% of an item’s lifecycle CO2 footprint is set early within the design phase of an item, meaning that if Cummins’ goal is to minimize a product’s environmental impact over its full lifecycle, Cummins’ engineers need to design products specifically for sustainability.

What is Designing for Sustainability?

Designing for Sustainability (DfS) is far more than just light-weighting. Instead, it’s a holistic approach that minimizes a design’s impact on the environment over its entire lifecycle.

Although Designing for Sustainability is a broad topic, this paper concentrates on the process of:

- Designing an item with no more material used than necessary to meet its strength and stiffness requirements.

- Making a mindful selection about component material from an environmental perspective.

- The importance of having a documented, actionable plan for item re-use, recycling, and remanufacturing.

- Designing a product from a near-net perspective, minimizing the energy and water required to post-process an item (e.g., machining after casting or forging an item).