Inspection for Quality and Field Maintenance Use Cases with Augmented Reality

Throughout a product’s lifetime,

inspection is a constant.

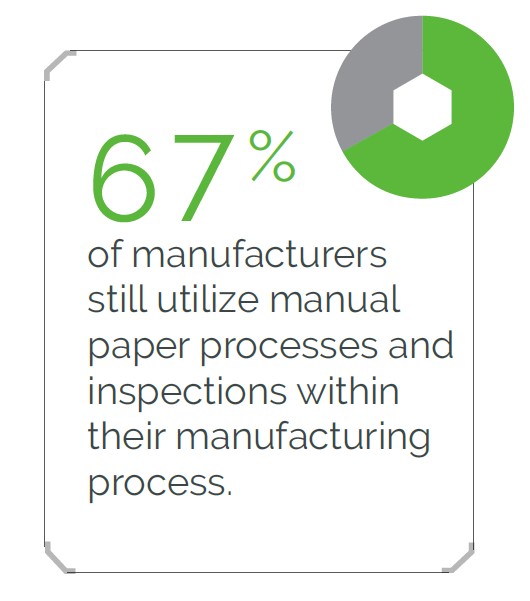

Between verifying product quality at the time of manufacturing before shipment and ongoing aftermarket maintenance and service, inspections ensure products continue to perform as intended. The importance of inspections cannot be overstated and yet for many original equipment manufacturers (OEMs), many inspection processes are still manual, involving paper-based processes and requiring a highly trained eye.

2D digital or paper-based instructions on how to perform inspections are often ambiguous, quickly outdated, and cumbersome to flip through while trying to execute the inspection at hand. Likewise, paper-based records on the results of inspections involve tedious data entry and difficult-to-navigate storage and retrieval. These processes prove to be incapable of democratizing knowledge widely to support continuous improvement.

When it comes to quality inspections and field service maintenance inspections, the limitations of manual and paper-based processes contribute to costly rework and scrap, customer dissatisfaction, and issues with employee safety, training, and retention.

To address these challenges head-on, OEMs are leveraging augmented reality (AR) for the most complex inspection use cases––and reaping meaningful business benefits.