ZF might be at the forefront of innovation, but its team was mired in traditional ways of working. Each division of the company – from electronics and software engineering to the IT value center – worked independently. Each team would complete its own stage of the product development process before passing the product on to the next division.

Its IT environments were just as fragmented. Each individual department used a wide range of tools, many of which didn’t mesh easily with one another – not to mention with tools from other divisions. All of which meant that teams often found themselves working from data that was already weeks old by the time it hit their inboxes.

In today’s product landscape, where new advancements need to reach the market faster than ever, this kind of siloed workflow could have held ZF back from market leadership.

About the Company

ZF is one of the largest and most respected Tier 1 automotive suppliers in the world. Its driveline, chassis, and safety systems are making the next generation of mobility clean, safe, and affordable for everyone. But to release new products fast and continue leading the market, it needed a PLM system that could get divisions and team members working together seamlessly.

The automotive industry moves fast: electrification, autonomous driving, integrated safety, motion control – every day, new innovations hit the market. And yesterday’s innovations quickly become standard for today’s drivers.

Which means companies like ZF have to keep their foot on the gas if they want to stay competitive. In over 100 years of operation, ZF has always led the way, seizing every opportunity for entrepreneurship and excellence. Today, the company supplies systems for passenger cars, commercial vehicles, and industrial technology around the world, from autonomous driving technology to electric mobility, safety measures, and motion controls.

New technology, old ways of working

ZF might be at the forefront of innovation, but its

team was mired in traditional ways of working.

ZF might be at the forefront of innovation, but its

team was mired in traditional ways of working.

Each division of the company – from electronics and software engineering to the IT value center – worked independently. Each team would complete its own stage of the product development process before passing the product on to the next division.

Its IT environments were just as fragmented. Each individual department used a wide range of tools, many of which didn’t mesh easily with one another – not to mention with tools from other divisions.

All of which meant that teams often found themselves working from data that was already weeks old by the time it hit their inboxes.

But modern product development is rarely so linear or siloed. The work of one division often influences another. Data gathered during testing can refine designs made earlier in the development process; adding a new capability to software might change the makeup and mix of electronic components.

In today’s product landscape, where new advancements need to reach the market faster than ever, this kind of siloed workflow could have held ZF back from market leadership.

See, think, act: the ZF approach to

product development

See, think, act: the ZF approach to

product development

The team needed a way to break the divisions out of their silos.

They moved from working as “divisions” to working as “system houses.” As system houses, all of the divisions work together on a single system simultaneously, with data, insights, and actions flowing freely both up and downstream.

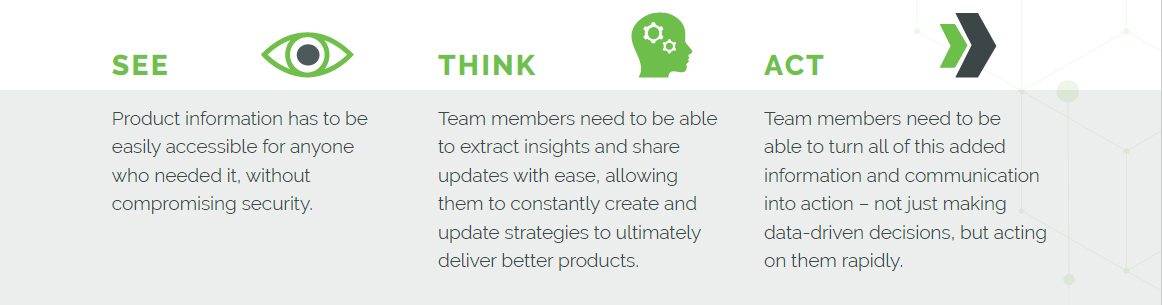

ZF’s goal is to help vehicles see, think, and act, and it approaches its product development with those same principles in mind. Which meant any solution had to be able to help the ZF team:

With these principles firmly in mind, ZF began to look for a product lifecycle management (PLM) solution that could enable this kind of collaboration.