- Windchill PLM

- BOM Management

- Collaborative Product Development

- Product Configuration Management

- Engineering Change Management

Polaris Drives a Connected Enterprise with a PLM-enabled Digital Thread

INNOVATOR SPOTLIGHT: Polaris Industries

Polaris Industries, a manufacturer of snowmobiles, all-terrain vehicles, and other high-quality outdoor recreational vehicles, is committed to realizing a connected enterprise that drives customer-focused innovations. The company is using a product lifecycle management solution from PTC to create and orchestrate a digital thread across design, engineering, manufacturing, sales, and service while leveraging augmented reality and the digital twin.

Polaris is driving a connected enterprise with a PLM-enabled digital thread

Polaris’ snowmobiles, all-terrain vehicles (ATVs), and other high-quality products fuel the passion of the outdoors for its customers and employees alike. Polaris strives to create a great end-to-end experience, including innovative connected products, customized purchase options, enhanced safety features, and rapid product repair. To achieve this vision, it needed to connect stakeholders across the company with accurate, up-to-date product data.

The company adopted a step-by-step approach to digital transformation, unlocking the power of its employees through PTC solutions. Polaris’ digital transformation journey focused on implementing and providing the processes, communications, and data that its employees could harness to best design, introduce, produce, and support innovative products. Windchill, PTC’s product lifecycle management (PLM) solution, was at the heart of this transformation.

– Matt Emmerich, Vice President & Chief Information Officer, Polaris Industries

Challenges: Outgrowing processes and tools

As the global leader in powersports, Polaris operates 30 brands and delivers enriching experiences and services that invite people to discover the joy of being outdoors. The company experienced tremendous growth over the past decade and established a larger global footprint. In the process, it outgrew its processes and tools and struggled to deal with the complexity of all the product options and variants.

To be able to mass customize its line of snowmobiles and ATVs quickly and efficiently and deliver the most innovative, high-quality vehicles in the market, Polaris needed to better connect and manage every step of its product lifecycle. The challenge was to equip its employees with the right tools to enable the company to stay ahead of customer expectations, while empowering riders with the right products, services, and experiences.

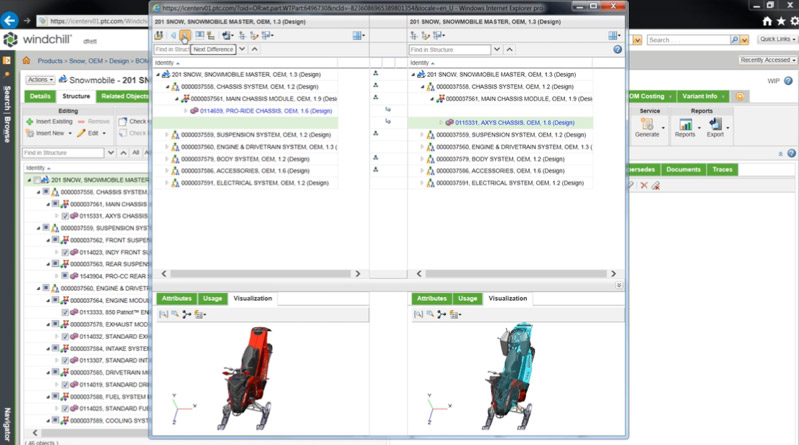

Side-by-side visualization capabilities let users quickly view and compare the physical and structural representation of the options selections.

– Matt Emmerich

– Jeff Goulet, Platform Director, Polaris Inc

Connecting the enterprise through a PLM-enabled digital thread of data

In today’s market, it’s essential for customers to be able to personalize or otherwise customize their products. To compete successfully in this environment, manufacturers such as Polaris must deal with the complexity of multiple product options and variances. With PLM, manufacturers can streamline the product development process and manage this complexity to realize efficiencies and drive innovation across the enterprise.

To mass customize its line of snowmobiles and ATVs and deliver the most innovative, high-quality vehicles in the market, Polaris needed to better connect and manage every step of its product lifecycle. Polaris continues to use and explore PTC’s Windchill enterprise product lifecycle management (PLM) solution to manage and orchestrate a digital thread of data across the enterprise. Windchill enables the company to react better and faster to change; engineer for choice; optimize costs; and break down the silos between engineering and manufacturing, marketing, sales, and service with closed-loop quality. This creates efficiencies and helps improve innovation across the enterprise.

This digital thread also extends into augmented reality (AR). Windchill’s AR Design Share functionality provides an efficient way to collect, create, manage, and maintain 3D experiences as part of the natural PLM process in a more consumable way.

The connectivity of Windchill paired with the collaborative aspect of PTC’s ThingWorx IoT (Internet of Things) platform has brought all areas of Polaris’ product development processes onto one platform..

PTC ThingWorx Navigate provides secure, quick, and easy access to rich product development data managed in Windchill through a set of contextual role- or task-based apps. Non-expert and expert users alike now spend less time searching for data and see the data they need ─ combined with data managed in other systems such as enterprise resource planning (ERP) ─in a simplified easy-to-understand interface.

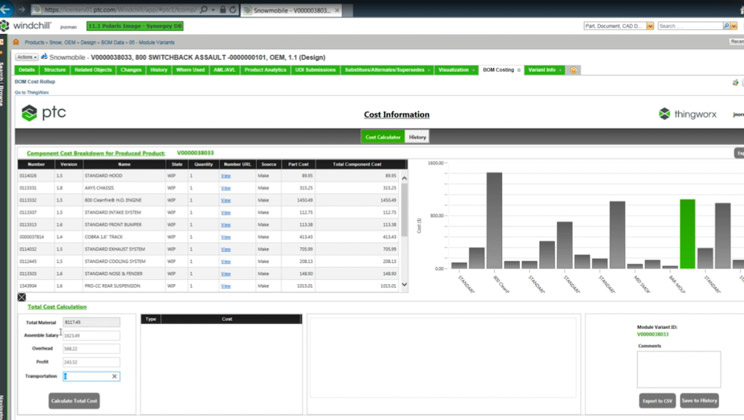

With the Costing Application in Windchill, users aggregate and view roll-up cost for BOM components

– Matt Emmerich

The digital data thread can link multiple functional areas across the product lifecycle

Bill of Materials Management

Windchill delivers a unified view of enterprise system data with bill of materials (BOM) management. Users can establish a single definition of an overloaded product platform with options and variants. Windchill’s ability to organize CAD models; engineering, manufacturing, and service BOMs; digital mockups; control logic requirements; and documents enables knowledge reuse from previous generations and iterations. This saves time spent on rework, searching for parts, or creating duplicate parts.

Configuration Management

Using options and variants, Windchill can configure a BOM specific to a certain model or variant. For example, with the Polaris RZR, it is easy to gather the information and deliver a BOM for each variant. This includes a visual and consumable representation of the overall product that can be easily analyzed and validated without having to scour through a complex overloaded BOM. This visual representation is helpful to the engineering and manufacturing groups and can also serve as a prototype for Polaris customers, allowing them to see what their vehicle will look like before purchasing. Customers can review the different models or variants and compare accessories, body types, and colors.

Windchill provides the optimized management and deployment of these variants, which translates into faster time to market and a better customer experience.

Bill of Materials Transformation

The seamless flow of information from engineering to manufacturing and service is critical. With PLM, product data changes are managed and applied in real time across the organization based on the most accurate relevant data. BOM transformation is a key component of the digital thread. Polaris utilizes Windchill to easily create a manufacturing BOM from the design or engineering BOM. During this process, each element of the manufacturing BOM is associated to the upstream design element. This quickens the production process by enabling engineering and manufacturing to work concurrently. It also improves overall product quality, reducing errors and in turn the number of service instances. With multiple interconnected BOMs within the product platform, each change made affects elements in the upstream engineering BOM, and downstream manufacturing and service BOMs.

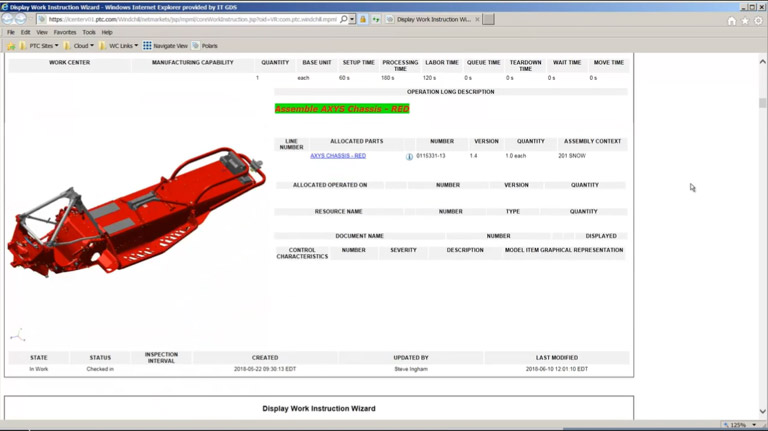

The continuous digital data thread simplifies the validation process by executing concurrent design and manufacturing planning. This helps create a better-quality product and speeds change propagation with associativity links. Manufacturing process plans and work instructions make it possible to design and create process plans and work instructions for every option in a product platform. The elements of the process plans and work instructions are linked to the components that make up the manufacturing BOM which, in turn, are linked to the components that make up the engineering BOM.

Change Management

capturing an issue or opportunity. The change request is sent to all appropriate stakeholders and expedited based on prioritization and urgency.

Stakeholders stay informed throughout the change process and can synchronize responses efficiently and in a timely manner.

The change management process in Windchill includes traceability to all components affected by the change. Change review and approval are expedited because all effected changes are centrally located. When a change is implemented, all affected elements are updated simultaneously. This assures an efficient change management process, which eliminates tedious and time-consuming rework and improves first-pass yield rates. The digital thread extends into augmented reality, or AR (next page).

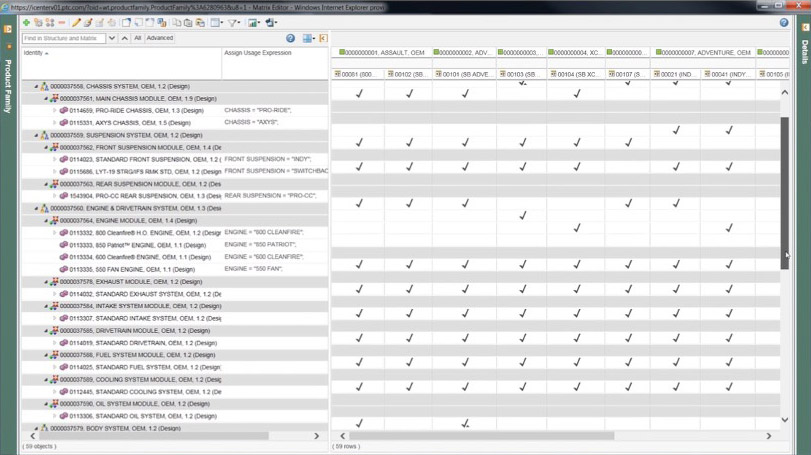

Family Management

Windchill creates an easy-to-follow hierarchy for configurable products. Beginning with the product family, users can define the family groups and product models that come under it. The family groups help organize the product models and the product models describe the SKU common configuration or partially configured offering. These cohesive family groupings allow users to easily access data without endlessly searching a poorly organized system.

Windchill provides easily definable objects, intuitive navigation that’s easy to set up and maintain, and distributes all definitions enterprise wide. This saves time and streams workflows. Not only is data easily searchable, but the user interface provides simple, easy-to-understand layouts and a matrix view, enabling users to quickly look over configurations and edit effortlessly as needed. Users can see a hierarchical list on the left side of the screen with the corresponding matrix view displayed on the right. With the editing tools, users can also see how changes made to the structure and logic affect other aspects of the family in this view. This ensures visual confirmation of changes made. If there are questions about certain module variants and parts, descriptions of attributes, uses and occurrences are all available to clearly understand the configurable product family.

A matrix view shows the impacts of changes made to product family structure and logic.

– Andy Burke, Publications Team Manager, Polaris Industries

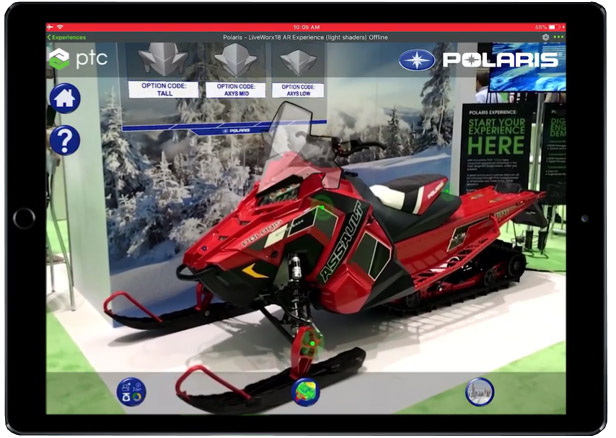

Digital thread Enables 3D augmented reality experience

In product development, visualizing what that product will look like can be difficult and creating physical models of that product is expensive and time consuming. While viewing CAD designs in 2D and 3D can be useful, it doesn’t offer the ability to visualize a product in physical space at full scale. With augmented reality, designers can place a CAD design virtually within a physical room to accurately visualize a current design built off real-time product development data.

A Polaris snowmobile configuration visualized in real-time and full-scale in the user’s environment

Windchill’s augmented reality (AR) design share functionality provides an efficient way to collect, create, manage, and maintain 3D experiences as part of the natural PLM process. The 3D AR experience is only possible through the digital thread and digital transformation. The CAD data, documents, components of the process plan, work instructions and other related digital content are all necessary components for developing and creating augmented reality experiences.

Windchill software helps digitally define and manage product data and bills of materials. These can then be leveraged and extended through PTC’s Vuforia platform to create AR experiences. With a Polaris snowmobile, for example, it’s easy to select which type of vehicle designers want to review and understand spatially how the vehicle functions and interacts with its various parts. Functions across the organization can select from a list of generated variants from Windchill to visualize data through AR. Users could also apply this functionality to various sales and marketing scenarios. For instance, dealers can provide buyers with an immersive experience on their show floors by visualizing virtual product options, colors, or accessories before buying.

Thingworx Navigate provides easy access to accurate, up-to-date product development data

ThingWorx Navigate provides quick, easy, and secure access to rich product development data managed in Windchill through a simple set of contextual roleor task-based apps. ThingWorx Navigate helps non-expert and expert users alike spend less time searching for data and presents the data they need in a simplified, easy-to-understand interface.

ThingWorx Navigate provides role- and task-based access to the data relevant to their role

Data managed in other systems, such as ERP, can be combined to provide a holistic view. With this capability, a user who needs access to a drawing of a part or assembly on the Polaris RZR no longer needs to contact and wait on an engineer. Instead, they just enter the part number and instantly get the most recent accurate drawing, eliminating miscommunication and any potential downstream design risks or rework. ThingWorx Navigate also promotes collaboration with the ability to view and measure part designs in the 3D application. Users can investigate stated problems and mark up 3D designs, effectively communicating the problem to other relevant stakeholders.

The connectivity of Windchill paired with the collaborative aspect of ThingWorx Navigate will bring all areas of Polaris product development process into one platform using PLM to create a digital thread of information. Employees from design to engineering, manufacturing, and service will be equipped with the tools they need to get their job done efficiently.

Costs will be reduced and product quality increased. Mass personalization of snowmobiles and ATVs will be made possible with greater configuration flexibility. By implementing these technologies, Polaris will not only empower its employees with the right tools. It will also give its riders a great end-to-end experience from customized purchase options to rapid product repair and enhanced safety and reliability.

Managing configurations and the product lifecycle

Polaris is streamlining its end-to-end process by connecting PTC’s Creo computer-engineering design (CAD) solution to an engineering bill of materials (eBOM) or manufacturing BOM (mBOM) in Windchill and then passing that information on to a service BOM (SBOM). The sBOM then flows out to parts lists and illustrations. This automated process will help increase Polaris’ agility to manage product configurations, options, and variants, unlocking the ability to more quickly deliver customized products to market.

By applying a filter for color, dynamic work instructions are generated based on the color variant selected.

Using connected devices to enhance the customer experience

The industrial design team at Polaris uses Creo to communicate with engineering and improve the product design process. At the same time, connected data from its products, factories, dealers, and the field are helping the company design customer focused features and products that deliver the best driving experience. Through use of the digital twin, it is speeding up product designs, delivery, and quality.

Connecting the enterprise

The connected enterprise is how Polaris makes sure all stakeholders work in unison, efficiently calling upon shared information. Connecting Creo CAD data from design to the mBOMS and then into an sBOM in Windchill has automated the process of sharing information downstream. This makes it possible to make faster decisions, accelerate the design and validation process, and bring new products to market faster.

– Greg Brew, Vice President of Industrial Design, Polaris Industries

While the company’s overall digital transformation is still a work in progress, Polaris has already started to identify significant business benefits.

See how Polaris and other manufacturers are ensuring that stakeholders use the same data to collaborate easily across engineering, manufacturing, and service.

- Digital Thread: Manage and orchestrate a digital thread of data across the enterprise leveraging BOM management, configuration management, BOM transformation, change management, manufacturing process management, and AR design share.

- Family Management: Plan product families and manage options, choices, and assignments in multi-year product structures.

- Augmented Reality: View first-hand variant-specific AR design review and visualization, as well as process plan visualization.

- Manufacturing Process Planning: Concurrently develop mixed-model assembly process plans.

- BOM Costing Application: Make a custom mashup of variant-specific cost tracking and roll-up.

- BOM Management and Global Platforms: Manage and link CAD data, BOMs, and visualization for a modular EBOM structure and generate options and variants for design verification and visualization.

- Change Management: Manage the change of a new option from EBOM to MBOM through process plans and work instructions.

- BOM Transformation: Associatively transform the BOM from engineering to manufacturing with options and logic.

- Role-based Access: Access digital product information depending on your role in the organization.

- Interference detection: Create variant-specific validations with DMU/interference analysis.

- Computational Fluid Dynamics: Improved product quality and speed time to market with its powerful analysis tools.

- Topology Optimization: Create innovative designs that meet engineering requirements

- Additive Manufacturing: Print with polymers and metal, allowing you to lower manufacturing costs and reduce costly scrap.