CREATING OPPORTUNITIES FOR STUDENTS

At RMIT University in Australia, educators rely on PTC’s software to prepare students for careers in Industry 4.0. LEAP Australia, a Platinum PTC Partner, assists RMIT University to utilise PTC’s suite of products including ThingWorx (IoT), Vuforia (AR), and Windchill (PLM) and help students to showcase the benefits of IoT, AR, and advanced data analytics to industry.

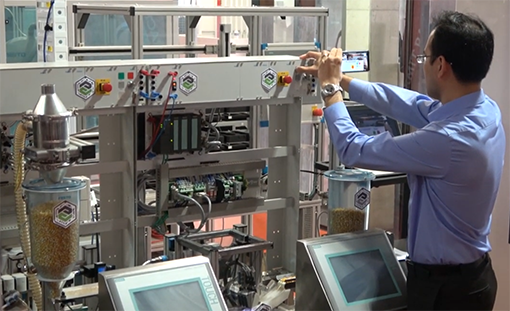

Dr. Chow Yin Lai, Lecturer in Automation at the RMIT School of Engineering, operates a mini-factory setup at the school, of which PTC’s software has become an integral piece. “By using PTC’s ThingWorx and Vuforia Studio, we have been able to enhance Using the Vuforia View app in the mini-factory At RMIT University in Australia, educators rely on PTC’s software to prepare students for careers in Industry 4.0. LEAP Australia, a Platinum PTC Partner, assists RMIT University to utilise PTC’s suite of products including ThingWorx (IoT), Vuforia (AR), and Windchill (PLM) and help students to showcase the benefits of IoT, AR, and advanced data analytics to industry. the learning aspects of our 9-year old mini-factory by exposing students to new Industry 4.0 technologies. Without changing any hardware, we were able to use ThingWorx and Kepware to connect the data via the cloud and then in just a

few hours we were able to easily and quickly build informative interactive dashboards with live system monitoring, also optionally displayed in AR, providing students and visitors with an easily accessible demonstration of IoT, AR and Digital Twin. This is important knowledge which I believe will ultimately help our graduates in a competitive job market. I believe this is an exciting time to be involved in this technology.”

This example outlines one way in which RMIT has positioned itself as a leader in ensuring that students are prepared to bring an extensive knowledge of technology to the workforce. The next sections outline four examples of projects at RMIT where educators and students demonstrate their commitment to pursuing the digital transformation of academia as students prepare for their future careers in Industry 4.0.

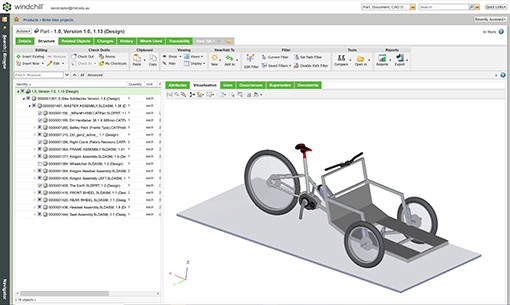

USING WINDCHILL FOR DESIGN COLLABORATION WITHIN STUDENT TEAMS

“By implementing PTC’s Windchill for PLM at RMIT, we are giving our engineering students the ability to understand how PLM benefits them working in a complex team environment – giving them exposure to the same challenges and workflows that are experienced daily by engineers operating out in industry,” says David Taylor, Lecturer, Industry Fellow, and Head of Engineering Learning Factory at the AMP in the School of Engineering. Taylor explains three benefits of teaching Windchill, the industry standard PLM tool, to students:

“As RMIT operates over several campuses, we are also able to demonstrate a complex multisite team environment that would be found in a national or international business. Students gain an appreciation of how PLM aids product development. As these tools have risen out of the desire for industry to continually increase productivity, practices such as Windchill PLM aids in the design & manufacture of a wheelchair accessible bike operating inside workflows become familiar to our students. Having data management and security provided by Windchill allows our teams to understand how important data control is, yet they can focus on the task at hand confident in the knowledge data is there when they need it, the correct version is being used, and that our industry partners are provided with the controls they expect. In short, with an effective PLM solution in place, our cross-functional teams are gaining valuable real-world experience through practice.”

DIGITAL TWIN ON DISPLAY USING VUFORIA STUDIO

At the Australian International Airshow, a biennial event held at Avalon, Victoria, Australia, RMIT students used AR to showcase a simulation-based digital twin of a model PC9 aircraft. This aircraft is used in the show by the Royal Australian Air Force Roulettes, the formation aerobatics display team. This was an opportunity for students from the aerospace department to present their research findings publicly and highlight their use of ANSYS Simulation and Digital Twin using Vuforia Studio.

HACKATHON SOLVES REAL WORLD INDUSTRY PROBLEMS

With the help of LEAP Australia, in 2018 RMIT University held an inaugural IoT/AR Hackathon to foster collaboration between the university and industry and provide students with learning opportunities to develop their skills with in-demand Industry 4.0 technologies. At the event, students work to solve real-world industry problems and present their solutions to a panel of industry judges. The students use ThingWorx and Vuforia Studio to incorporate cutting edge IoT and AR technology into their projects. This hackathon is a great way for the university to put on display the interest, pursuit, and active deployment of student knowledge in Industry 4.0 technology and operations, and for industry representatives to be exposed to all of the impressive work they are doing.

ENGAGING NEXT-GENERATION OF STUDENTS WITH ADVANCED VISUALIZATION

At the 2019 Australian F1 Grand Prix, RMIT educators, in conjunction with Ford Australia and the ATLAS Innovation Training Centre, used AR experiences developed in Vuforia Studio to showcase their work to the next-generation of potential STEM students. RMIT Racing also used the latest simulation technology from PTC Partner, ANSYS Inc, as well as PTC’s Vuforia AR technology to create an AR experience that displays aerodynamic flow over their 2017 F-SAE race car. By taking the data obtained from ANSYS CFD simulation results and virtually overlaying them on a real vehicle with AR, the RMIT Racing team members are now able to help new recruits to better visualize and understand the complex aerodynamic interactions on their vehicle much more easily.

THE FUTURE WORKFORCE

These four projects represent a selection of the numerous ways in which RMIT University utilizes PTC technology to infuse the latest Industry 4.0 technology into the classroom and to push the digital transformation of academia. Educators at RMIT know that teaching these technologies to students is critical in bridging the gap between education and industry. Pier Marzocca, Professor and Associate Dean of the School of Aerospace Engineering explains, “our goal is to allow all engineering students to experience these state-of-the-art virtual prototyping and Industry 4.0 tools, and in doing so, gain new employability skills and competencies that are increasingly be in-demand across our extensive network of industry partners. Our collaboration with LEAP Australia has allowed us to excite younger students and expose them to the opportunities found in careers in STEM, which can be nurtured and brought to life through universities that offer these Industry 4.0 resources.”

"By using ThingWorx and Vuforia Studio, we have been able to enhance the

learning aspects of our mini-factory by exposing students to new Industry 4.0

technologies.”

Dr. Chow Yin Lai

Lecturer in Automation, RMIT School of Engineering