- BYU Manufacturing Engineering program partners with PTC Academics to prepare next generation of smart manufacturing leaders

- Academic program looks to fill in the gap of skilled workers that many global manufactures are facing

For over fifty years, the Ira A. Fulton College of Engineering has led Brigham Young University’s (BYU) engineering discipline and currently awards 11 distinct and prestigious degree programs to its more than 4,000 students. The institution enriches graduates with the opportunity to leverage an exceptional and celebrated technical education coupled with the leadership skills needed to take on tomorrow’s greatest engineering challenges.

The Challenge

There is an emerging worldwide trend of IIoT-focused curriculum growth within leading colleges and universities, resulting from increasingly complex manufacturing operations and the skills gap shortages in the industry. As such, educators are rapidly seeking to motivate and prepare students for careers in the field.

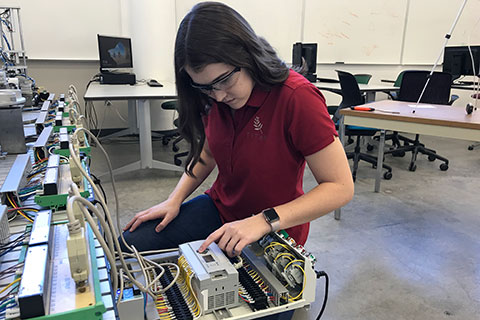

The BYU Manufacturing Engineering department has recognized that in order to best prepare its students to successfully enter today’s manufacturing industry their academic experience must embrace a hands-on approach. BYU sought to replicate the kind of environment students will encounter in practice throughout their careers, in the classroom. One where the tools and technology that graduates will use are woven into the curriculum and beyond. The endeavor would seek to include opportunities such as internships and research projects with local manufacturers. The hope of stakeholders in this arena is that these types of university-industry collaboration programs will evolve and develop innovative business and technology solutions in the era of Industry 4.0 that will benefit both students and their future employers.

BYU’s undertaking included the full implementation and integration of smart manufacturing principles that merged operational and information technology into both the undergraduate and graduate levels of study. From a practical perspective, the introduction of this technology in undergraduate curriculum, for example, would enable students to engage in a senior capstone – independent research experience within smart manufacturing simulators – giving them the opportunity to further develop advanced skills in smart production.

The Solution

BYU chose to partner with PTC because it of its industry expertise and technology that is compatible with the broad range of IT and OT systems deployed in the industry. PTC Academics is many things - a team of educators, creatives, and technologists who are passionate about providing gamechanging technical training in Augmented Reality and the Industrial Internet of Things, and engineering. As BYU’s Manufacturing Engineering department discovered, PTC Academic’s team is uniquely equipped to understand the needs of educators looking to prepare their students for the current and next-generation workforce. Technology is advancing rapidly, and the PTC Academic product suite is designed to bring the cutting-edge software used by industry leaders to the classroom. Combined with resources and curriculum, PTC’s Academic software packages give educators all the tools they need to be successful.

The portfolio of tools and solutions implemented by BYU into the academic and real-world experience of its students included: Augmented Reality (AR) with Vuforia Studio, Industrial IoT with ThingWorx, and industrial connectivity with Kepware.

Yuri Hovanski, Associate Professor of Manufacturing Engineering, Bringham Young University

To engage BYU students with IIoT, ThingWorx has combined technology, interactive online courses, and hands-on learning into connected workshops, enabling practical experience in the classroom. And engaging videos, projectbased challenges, and dynamic learning exercises can all be accessed on-demand by educators and students alike. From a practical in-the-field perspective, the modules provide manufacturers with real-time visibility into factory floor operations.

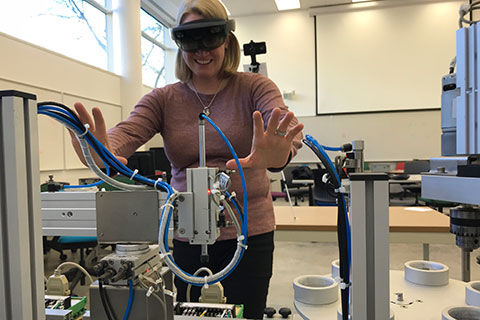

Vuforia Studio has also provided all the components needed for BYU students and educators to quickly and easily develop public Augmented Reality experiences. Faster AR authoring through the drag and drop interface has made it easy for students with no prior coding knowledge to get up and running quickly, for use in and outside the classroom.

The Outcome

The implementation of PTC Academics into the BYU Manufacturing Engineering program has enhanced the process of sending students offsite to engage in interdisciplinary projects with local manufacturers to aid in their smart manufacturing efforts. Examples include companies such as Boeing, Northrup Grumman, Fiero Fluid Power, Inc., Autoliv and Barnes Bullets. The partnerships with local manufacturers have not only set students up for life after college in the modern factory, but has also given manufacturers more insights from actionable machine data. The impact of these relationships includes identification of raw truth information from machines, insights gained on the most paramount needs of specific departments, support of management for IIoT implantation, and changing the way companies traditionally address machine throughput efficiency.

With the introduction of these innovations, BYU’s partnership with PTC has proven to be a win-win for students, professors, and local manufacturers alike. In fact, some students participating in this program are receiving offers from organizations at the forefront of IoT innovation – proving that this formula has paid dividends for students long after their time on campus. Finding a program that can help students seamlessly transition from academics to a career of choice is something that is truly unique and will prove to be a differentiator within the BYU Manufacturing Engineering department.