Additive Manufacturing: What is the 3MF format?

- 11/18/2021

- Tempo di lettura : 4 min.

Written by Jose Coronado, Creo Product Manager

The 3D manufacturing format (3MF) is an industry-supported file format that design applications can use to send full-fidelity 3D CAD models to a mix of other applications, platforms, services, and printers.

With the 3MF specification, companies can focus on innovation rather than on basic interoperability issues. Best of all, it is engineered to avoid the problems often associated with other 3D file formats.

The 3MF Consortium is a non-profit organization that provides the corporate and legal infrastructure for 3MF, enabling groups to establish and operate standards and to collaborate on source code development.

The 3MF Consortium has been working on a set of specifications to create a file format that is complete, human readable, simple, extensible, unambiguous, and free.

The video above shows how you might prepare to print a part or assembly using the format in Creo.

What problems does 3MF solve?

For the additive manufacturing community, 3MF addresses several issues:

- It provides one industry-backed format, from design to print, with no loss of information.

- It provides a clear definition of manifoldness, eliminating the possibility of self-intersections and overlaps. Units, colors and properties are also clearly specified.

- It is native in Microsoft Windows and Office.

- All the information required to manufacture a part is encompassed with a single compact file.

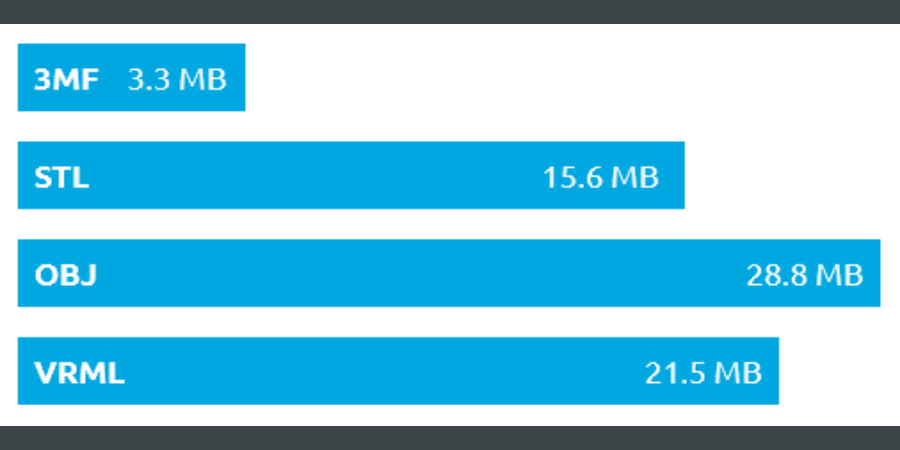

Image: Comparison of data saved in multiple file formats.

Benefits of 3MF

When using 3MF, you can take advantage of several features, including:

- Sending a color model to a print service

- Printing lattice structures

- Incorporating texture

- Including support structures with the model

- Assigning materials

- Printing an object with the specific size and dimension

- Managing a full AM build tray

- Tracking parts in production systems

3MF and Creo

PTC is a member of the 3MF Consortium. Why should 3MF matter to Creo users?

To start, you can export 3MF files from Part or Assembly mode, or from the tray assembly. From there, you can directly send models to the 3D printing preparation software that came with your 3D printer. Or send models for visualization to a shop floor using standard Windows applications.

If you need to do nesting, printability checks, or create support structures, do it directly in the tray assembly. Also, because the tray assembly is a data-managed object in Windchill, you can vault the job preparation data in your PLM system to replicate the prints you created today at any point in the future.

What's New in Additive Manufacturing?

Lattice structures, self-supporting geometries, biomimicry: See how additive manufacturing is changing design.